Occupational Dermatitis Management: A Comprehensive Guide to Best Practices for Workplace Skin Health

Explore best practices in occupational dermatitis management to enhance workplace skin health, reduce inflammation, and improve productivity.

Estimated reading time: 10 minutes

Key Takeaways

- Prevention first: Minimize exposure through substitution, engineering controls, and proper PPE.

- Early detection: Use detailed histories, patch testing, and digital tracking to distinguish irritant vs. allergic reactions.

- Structured skin care: Gentle cleansers, fragrance-free emollients, and barrier creams restore and protect skin integrity.

- Workplace controls: Environmental ventilation, spill protocols, job rotation, and ergonomic adjustments reduce hazards.

- Ongoing education: Employee training, surveillance, and multidisciplinary collaboration drive sustained improvements.

Table of Contents

- Understanding Occupational Dermatitis

- Best Practices for Management

- Workplace Preventive Measures

- Role of Occupational Health Professionals

- Case Studies and Examples

- Conclusion and Next Steps

- FAQ

Understanding Occupational Dermatitis

This section explores causes, forms, symptoms, and industry relevance to lay the foundation for effective management.

Causes of Occupational Dermatitis

- Chemicals and irritants: wet work (water), detergents, solvents, acids, cleaning agents, mechanical friction.

- Allergens: metals (nickel), rubber accelerators, epoxy resins, plant proteins.

Forms of Contact Dermatitis

- Irritant Contact Dermatitis (ICD): Dose-dependent skin damage from direct contact; ~68% of occupational cases; common in healthcare and hairdressing.

- Allergic Contact Dermatitis (ACD): Immune-mediated reaction to sensitizing substances (chemicals, dyes, fragrances, formaldehyde).

Symptoms and Impact

- Acute: redness, scaling, fissures, blisters.

- Chronic: lichenification, persistent itching.

- Hands affected in 80% of cases; other areas reflect exposure routes.

- Nearly 50% report impaired quality of life: pain, sleep disruption, social stigma.

Industry Relevance

Occupational dermatitis spans multiple sectors:

- Healthcare: frequent hand washing and glove use.

- Hairdressing: shampoo chemicals, dyes.

- Food handling: wet work, cleaning agents.

- Agriculture: plant proteins, pesticides.

Sources:

American Family Physician (2016)

PMC article on occupational dermatitis

PMC cases study article

Best Practices for Management

Implement these layered strategies to prevent, detect, and treat occupational dermatitis efficiently.

1. Minimizing Exposure

- Perform chemical inventories and risk assessments to pinpoint high-hazard substances.

- Substitute less irritating or allergenic compounds when feasible.

- Apply engineering controls:

- Protective barriers (glove liners, sleeves).

- Local exhaust ventilation at chemical use stations.

- Improved general ventilation to reduce airborne irritants.

2. Early Detection & Diagnosis

- Take detailed occupational histories: tasks, exposure duration, PPE use.

- Perform patch testing after three months of persistent dermatitis to distinguish ICD from ACD.

- Leverage digital symptom tracking apps such as the detailed rash-tracking guide to log flare-ups and triggers.

- Incorporate AI for faster insights (see AI-driven rash diagnosis).

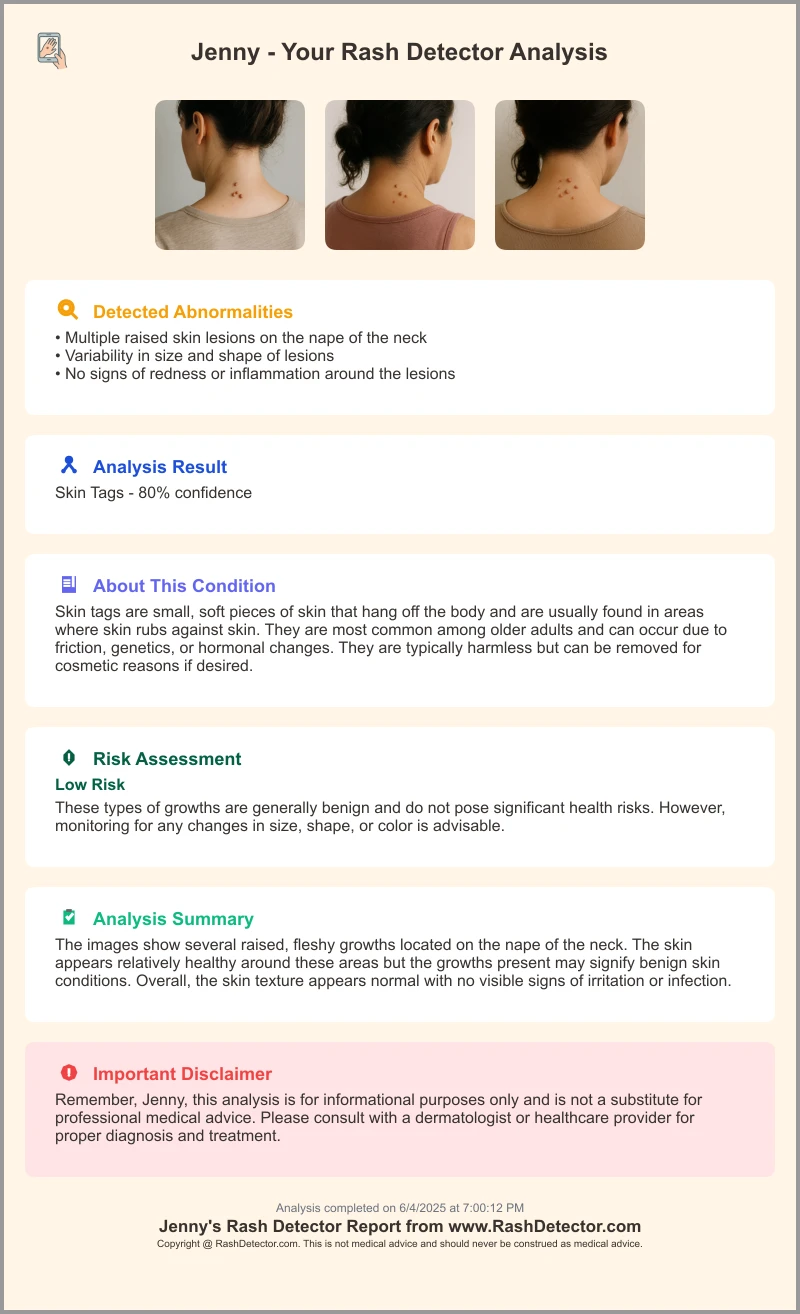

For on-the-spot skin analysis, try Rash Detector, an AI skin analysis app providing instant feedback based on photos. Below is a sample report.

3. Decontamination & Skin Care Routines

- Use gentle, pH-balanced cleansers immediately after exposure to remove contaminants.

- Apply fragrance-free emollients after every wash to restore skin barrier.

- Employ barrier creams 15–30 minutes before high-risk tasks; note they supplement—not replace—gloves.

Sources:

American Family Physician (2016)

PMC article on occupational dermatitis

Workplace Preventive Measures

Design workplace controls and policies to minimize dermal hazards and support skin health.

Personal Protective Equipment (PPE)

- Select gloves based on chemical resistance and allergy risk: nitrile, latex, vinyl.

- Provide training on correct donning/doffing to avoid cross-contamination.

- Rotate glove types to reduce sensitization and contact allergy.

Environmental Controls

- Ensure adequate general ventilation and install local exhaust near chemical operations.

- Use closed transfer systems for liquid chemicals; label all containers clearly.

- Maintain spill response protocols and accessible decontamination stations.

Job Modification & Rotation

- Alternate high-exposure tasks among staff to allow skin recovery periods.

- Introduce ergonomic adjustments to reduce mechanical friction and moisture build-up.

- Schedule micro-breaks for skin rest and reapplication of barrier creams.

Sources:

American Family Physician (2016)

PMC article on occupational dermatitis

PMC cases study article

Role of Occupational Health Professionals

Occupational health teams drive program success through hazard control, monitoring, and education.

Hazard Identification & Risk Assessment

- Conduct regular walk-throughs to spot potential skin hazards.

- Use chemical risk matrices and exposure monitoring data to rank priorities.

- Collaborate with safety engineers to refine control measures.

Surveillance & Record-Keeping

- Implement routine skin checks using tools like the Nordic Occupational Skin Questionnaire.

- Keep detailed logs of dermatitis cases, interventions, and outcomes for trend analysis.

- Share anonymized data with management to support resource allocation.

Policy & Protocol Development

- Draft SOPs for:

- Skin protection measures.

- Emergency decontamination response.

- Incident reporting and referral pathways.

- Embed these protocols within the broader occupational health and safety manual.

Employee Training & Education

- Offer modular training on hazard recognition, correct PPE use, decontamination, and self-care drills.

- Use hands-on simulations (e.g., mock spills) to reinforce concepts.

- Evaluate comprehension through quizzes or return demonstrations.

Follow-Up & Program Evaluation

- Schedule periodic dermatology referrals for persistent or recurrent cases.

- Review KPIs (incidence rates, severity scores) quarterly.

- Adjust controls, substitutes, and policies based on metrics and feedback.

Sources:

American Family Physician (2016)

PMC article on occupational dermatitis

Case Studies and Examples

Real-world successes demonstrate how focused interventions reduce dermatitis rates.

Healthcare Setting Example

- Baseline prevalence: 8.2% of staff with hand dermatitis.

- Interventions: enhanced hand hygiene protocols, glove rotation, barrier-cream program, training refreshers.

- Outcome: 45% reduction in dermatitis cases over 12 months.

- Key factors: multidisciplinary collaboration, leadership support, regular monitoring.

(Source: PMC cases study article)

Food Processing Plant Example

- Issue: 6.5% of workers affected by dermatitis due to harsh cleaning agents.

- Interventions: replaced caustic cleaners with enzyme-based formulations; upgraded local exhaust; mandatory skin-care workshops.

- Outcome: incidence dropped to 2.1% within one year.

- Lessons: targeted substitution, engineering controls, hands-on training.

(Source: PMC article on occupational dermatitis)

Extracted Lessons

- Multidisciplinary teams (safety, health, operations) achieve sustained improvements.

- Continuous education and real-time monitoring reinforce behavior change.

- Visible management commitment drives employee engagement.

Sources:

PMC cases study article

PMC article on occupational dermatitis

Conclusion and Next Steps

Implementing a robust occupational dermatitis management program requires layered controls, proactive monitoring, and ongoing education.

Key Best Practices

- Exposure minimization via substitution and engineering controls.

- Early detection through detailed histories and patch testing.

- Structured skin care: gentle cleansing, emollients, barrier creams.

- Correct PPE selection, fitting, and rotation.

- Comprehensive environmental controls and safe storage.

- Clear policies, routine surveillance, and systematic training.

Actionable Recommendations

- Employers:

- Perform regular risk assessments and chemical inventory reviews.

- Provide and maintain task-appropriate PPE and skin care supplies.

- Facilitate ongoing training and enforce a no-blame reporting culture.

- Employees:

- Report early symptoms to supervisors or occupational health staff.

- Adhere to PPE protocols and skin care routines.

- Participate actively in training modules and drills.

- Joint Efforts:

- Review incidence data quarterly and adjust controls as needed.

- Share success stories in team meetings to reinforce best practices.

- Keep policies updated as new research and products emerge.

By integrating these strategies, organizations can reduce occupational dermatitis incidence, boost productivity, and enhance worker wellbeing. A committed, data-driven approach aligns health, safety, and operational performance for long-term success.

Sources:

American Family Physician (2016)

PMC article on occupational dermatitis

PMC cases study article

FAQ

How can I prevent occupational dermatitis in my workplace?

Start with hazard identification and substitution of irritants, implement engineering controls for ventilation, provide appropriate PPE, and enforce structured skin-care routines.

What’s the difference between irritant and allergic contact dermatitis?

Irritant contact dermatitis (ICD) is a direct, dose-dependent response to damaging agents. Allergic contact dermatitis (ACD) is immune-mediated, occurring after sensitization to specific allergens.

Which PPE is most effective against skin hazards?

Select gloves based on chemical resistance and allergy profile (nitrile, latex, vinyl), train employees on proper donning/doffing, and rotate glove types to reduce sensitization.

How often should workplace skin surveillance occur?

Routine skin checks—such as quarterly assessments—and continuous digital symptom tracking help identify early signs and adjust controls promptly.

When should I refer an employee for dermatology evaluation?

Refer staff with dermatitis persisting beyond three months despite controls or those with suspected allergic reactions requiring patch testing and specialist care.